Our Projects

Browse Our

Project Gallery

A selection of manufacturing, e-mobility, defense, and industrial transformation projects delivered across automotive, battery, and advanced production environments.

- All

- Aerospace & Defense

- Automotive & E-Mobility

- Healthcare & Life Sciences

- Climate Tech & Energy

- Technology & Electronics

- EV manufacturing

Romeo Power – Battery Production Industrialization

Scaling advanced lithium-ion manufacturing by designing automated processes, optimizing capital deployment, and integrating robotics and precision joining technologies to enable high-efficiency production.

Tesla – EV Manufacturing Readiness

Manufacturing guidance to accelerate EV launch readiness, aligning product design with production systems, streamlining assembly processes, and strengthening supplier integration to support rapid scale-up.

AM General – Defense Technology Advancement

Power rolling chassis, autonomy, and survivability initiatives, developing technology roadmaps and enabling global collaboration to position future defense platforms for modernization.

U.S. Army – MRAP RG31 Modernization Support

Modernization of the MRAP RG31 platform capabilities integration across mobility, lethality, and survivability systems in collaboration with key defense partners to ensure mission-ready performance.

Bollinger Motors – EV Production Enablement

Transition from prototype to full scale production by establishing manufacturing processes, tooling strategies, and compliance frameworks that supported scalable EV build-out.

Chrysler / DaimlerChrysler – Vehicle Launch Optimization

Manufacturing optimization for major vehicle programs, improving tooling strategies, refining production processes, and applying operational excellence methods to ensure efficient, high-quality launches.

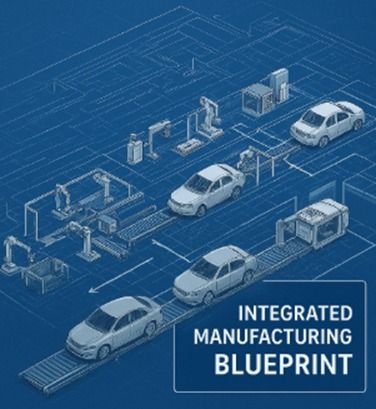

Kingdom Motors Beijing – Advanced Manufacturing Support for Harbin Assembly Plant

Provided comprehensive advanced manufacturing services for Kingdom Motors’ new assembly facility in Harbin. Work included full plant layout development, process engineering, scroll and workstation design, PC&L flow optimization, and conveyor/carrier system engineering. Delivered an integrated manufacturing blueprint that improved throughput, reduced material handling complexity, and aligned the plant with global automotive best practices.

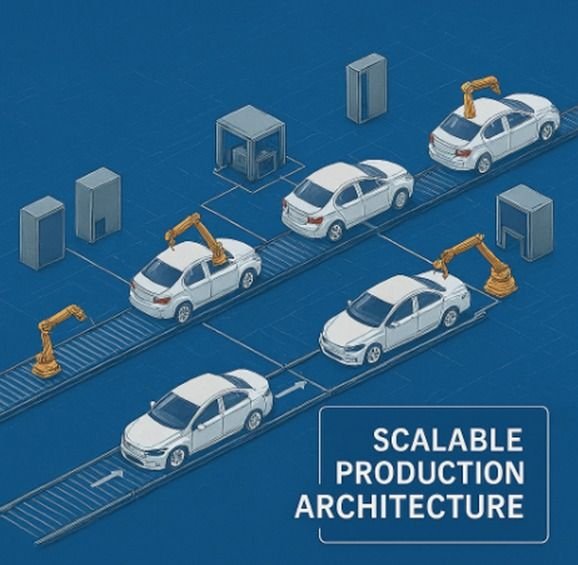

PSA, Poland – Complete EV Vehicle Assembly Plant Advanced Engineering

Led the advanced engineering program for PSA’s electric vehicle assembly plant in Poland. Scope included end-to-end process definition, equipment strategy, ergonomic studies, line balancing, and integration of EV-specific manufacturing requirements. Developed a scalable production architecture that supported PSA’s transition toward electrification while meeting European regulatory and quality standards.

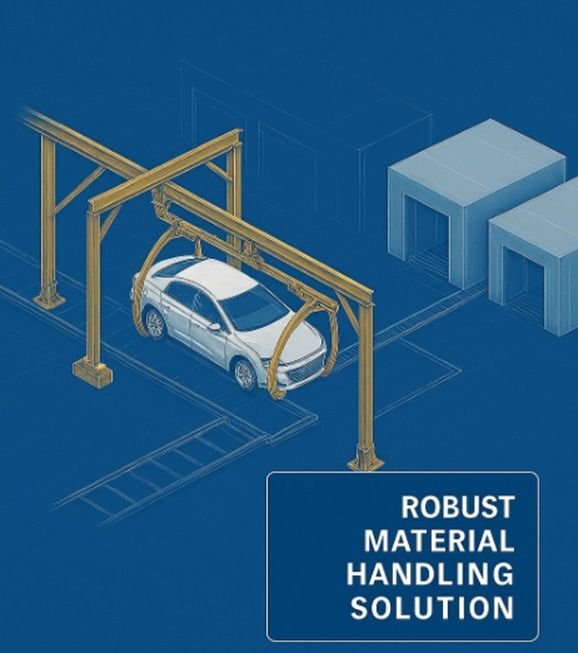

JPM, Sterling Heights MI – Paint Shop Conveyor & Structural Design

Delivered conveyor system engineering and structural design services for JPM’s paint shop operations in Sterling Heights. Work included carrier selection, overhead and floor-mounted conveyor layouts, structural load analysis, and integration with paint booth and curing systems. The result was a robust, maintainable, and high-efficiency material handling solution tailored to automotive paint operations.

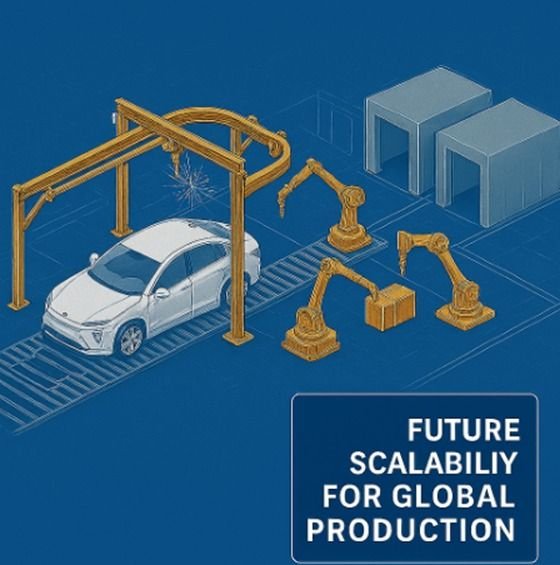

NIO – Santa Clara, California – Manufacturing Concept & Assembly Process Development

Supported NIO’s U.S. engineering center with early-phase manufacturing concept development and assembly process definition. Created conceptual layouts, process flows, and build-sequence strategies for next-generation EV platforms. Ensured alignment between product engineering, manufacturing feasibility, and future scalability for global production.